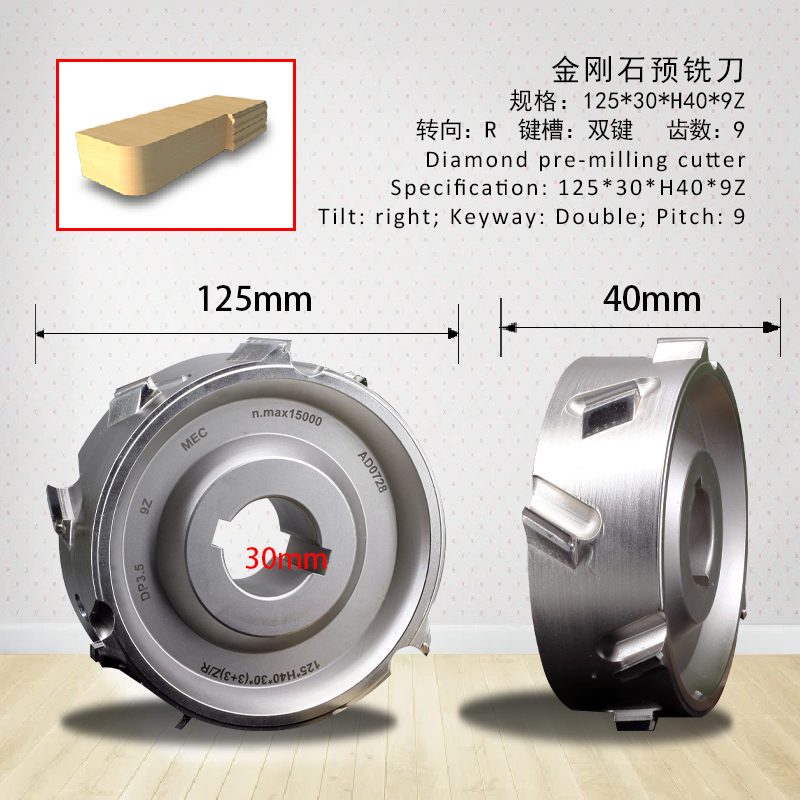

Diamond pre-milling cutters are high-precision, long-lasting milling cutters used in woodworking and panel processing.

Featuring diamond cutting edges, they are specifically designed for aligning panel edges, removing burrs, and trimming panel joint surfaces, ensuring smooth and seamless panel joining.

They significantly improve processing efficiency and accuracy and are widely used in fully automatic edge banding machines and straight/curved edge processing.

Key Features and Advantages:

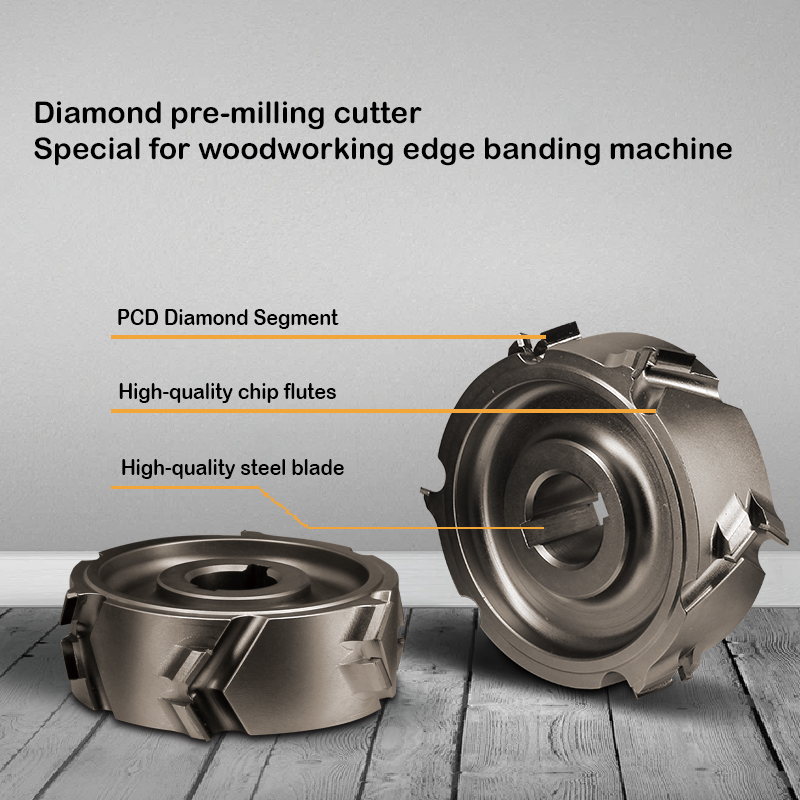

Ultra-hard blade: Made of diamond material, offering extremely high hardness and wear resistance, far exceeding traditional carbide tools, resulting in a longer service life.

High-precision machining: The tool's cutting edge is sharp and stable, achieving a smooth, chip-free, and burr-free cutting effect, ensuring perfect panel joining.

Improved efficiency: The long tool life reduces replacement frequency; the adjustable design eliminates the need for frequent axial adjustments, significantly saving working time.

Optimized structure: The tool is typically designed with spiral chip evacuation grooves, facilitating chip removal and ensuring cutting quality.

Wide application: Suitable for edge banding and trimming of various panel materials such as particleboard, medium-density fiberboard (MDF), and solid wood composite panels.

Working Principle:

When installed on an edge banding machine or machining center, the diamond pre-milling cutter rotates at high speed, precisely cutting the top, bottom, front, and back edges of the panel.

This removes unevenness and excess material from the edges, laying a perfect foundation for subsequent edge banding or joining processes.

Main application scenarios:

Furniture manufacturing (edge processing of panel furniture and solid wood furniture)

Cabinet manufacturing

Flooring and wall panel processing

Fine edge processing of various types of wood and engineered wood panels.