When grinding high-speed steel tools with a CBN grinding wheel, after the wheel is dressed with a roller or silicon carbide grinding wheel,

the abrasive grains and binder on the wheel surface are flat, and the CBN abrasive grains do not protrude.

At this point, the grinding ability of the wheel is relatively poor. The specific surface morphology of the grinding wheel surface is as follows:

When we use the grinding wheel without dressing it first to grind high-speed steel workpieces, workpiece burning occurs.

After grinding several workpieces with the same parameters, the surface morphology of the grinding wheel changes, with the abrasive grains protruding from the binder,

resulting in a more "open" grinding wheel surface. At this point, the burning phenomenon disappears. The surface morphology of the grinding wheel at this stage is as follows:

To directly achieve this state, we can do so through dressing followed by sharpening.

In actual production, if we want to avoid burning, and sharpening after dressing is inconvenient, we can reduce the feed rate when grinding the first few workpieces to prevent burning and defective products.

After grinding a few workpieces, the surface morphology of the grinding wheel will reach this (open) state, at which point we can increase the feed rate to the normal value and proceed with normal production.

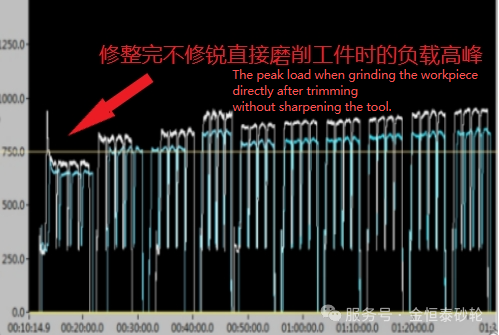

Load diagram during slotting production of high-speed steel milling cutters:

In the image above, because the grinding wheel was dressed but not sharpened, the load on the first groove during the grinding process changes from high to low to a normal load, and the surface morphology of the grinding wheel changes from "closed" to "open."

During this process, if the load reaches a certain level, it will cause workpiece burning. Therefore, we reduce the load by decreasing the feed rate or sharpening the grinding wheel to reduce defective products.

In the subsequent grinding process, the load will gradually increase as the number of grinding cycles increases and the abrasive grains wear down.

When the load increases to a certain level, it will again cause workpiece burning. At this point, the grinding wheel needs to be sharpened, and if the shape does not meet the requirements, the grinding wheel needs to be dressed again.