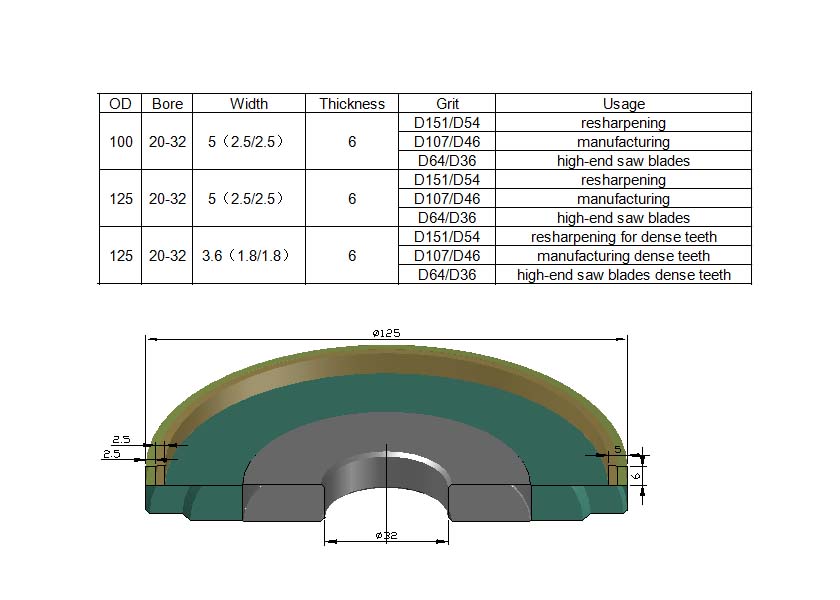

amasondo edayimane okugaya ama-carbide saw blades ahlukahlukene aphezulu 12a2 125X32X5(2.5/2.5)X6

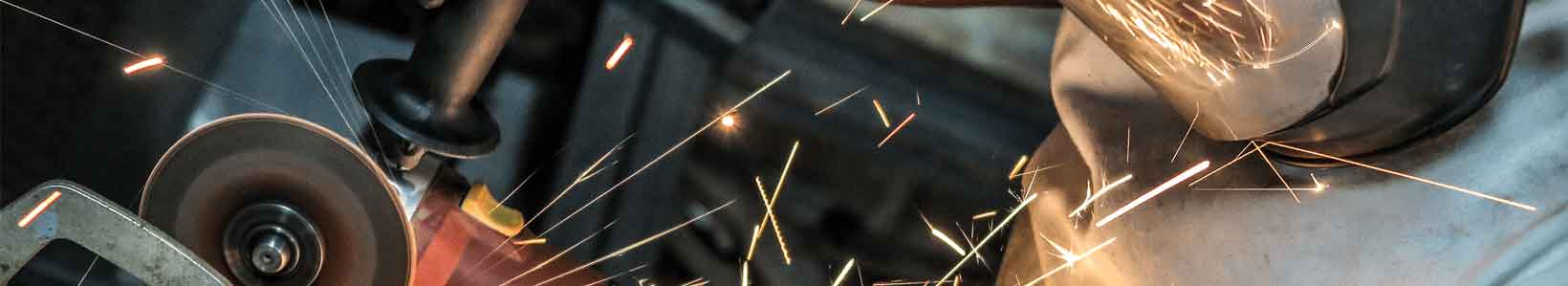

Isondo lokugaya idayimane le-resin bond lisetshenziswa kakhulu ekugayeni i-tungsten carbide circular saw blade.Unqenqema lokugaya lubushelelezi, futhi lubukhali futhi lunempilo ende yesevisi.

Isondo le-resin bond diamond lapping lisetshenziselwa ukucutshungulwa kwesikrini esikhundleni sokuxhaphazeka kwamahhala kwamahhala.Ingathuthukisa ukusebenza kahle kokucubungula kwesikrini esibonisiwe kanye nekhwalithi yendawo ephezulu, futhi yehlise izindleko.Inezinga eliphezulu lokususwa kwezinto kanye nokubangwa kahle kwendawo.

Isondo lokugaya idayimane le-resin lisetshenziselwa ukuqeda ukugaya amathuluzi e-tungsten carbide futhi lingathola isiphetho esiphezulu se-workpiece.

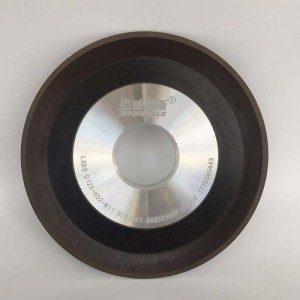

Amasondo okugaya okuphezulu:

Izimo: 12A2, 6A2

Ama-Abrasives: Idayimane

Isibopho: I-Resin

I-Workpiece: Amazinyo e-Carbide

Ingxenye Yokugaya: Ngaphezulu kwamazinyo

Izici: Ukucija okuhle nokusebenza kahle okuphezulu, ukuqina, ukulingana namaholoholo nokugaya okuhle ngesikhathi esifanayo, kwenza ucezu lokusebenza lube flatness oluhle nokushelela.

Kungaphansi kwaziphi izimo lapho ama-alloy saw blades adinga ukucijiswa.

Uma ikhwalithi yokusika ingahlangabezani nezidingo ezinjengokuxubha komkhiqizo nokumahhadla.Idinga ukucijwa ngokushesha.

Lapho unqenqema lokusika lufinyezwa ngaphezu kuka-0.2mm, kufanele lulolwe.Ayikwazi ukukala ukufinyeza konqenqema ngesibonakhulu ekukhiqizeni kwangempela, ngokuvamile isebenzisa isikhulisi ukuze ihlole.Uma kunomugqa omhlophe emazinyweni, udinga ukulolwa.

Lapho amandla okusika ekhuphuka kakhulu, kungcono ukungalindi ukuthi lesi simo senzeke ngaphambi kokulola i-saw blade

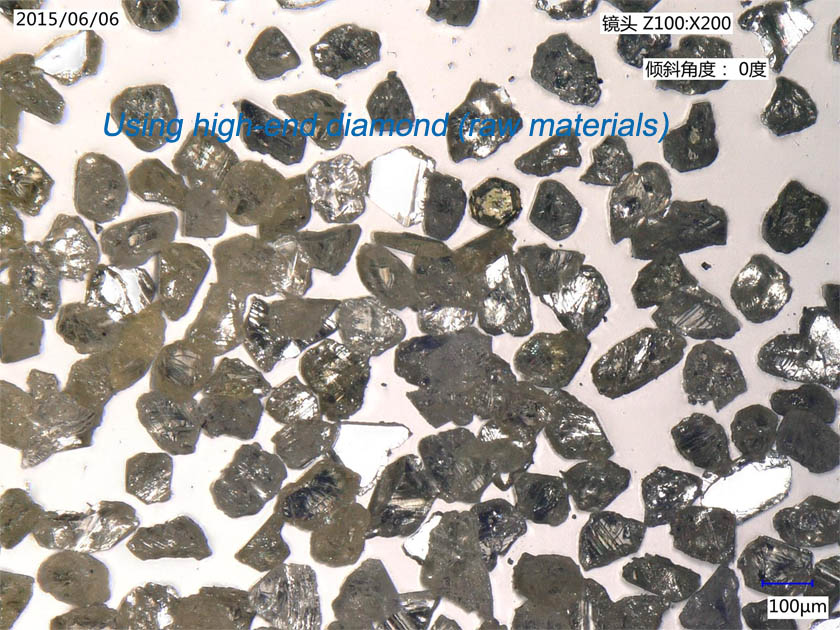

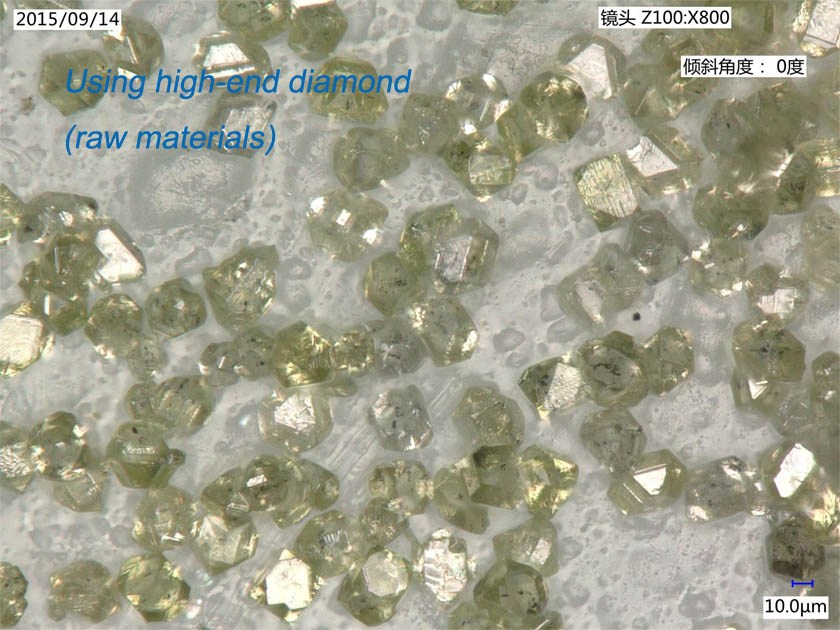

usebenzisa idayimane eliphezulu (izinto ezingavuthiwe)

Khetha amasondo ahlukene okugaya ngokusho kwama-cnc grinders ahlukene nama-saw blades

Inqubo yokugaya ye-back angle yokugaya ama-saha blade

Inqubo yokugaya:

Uma isivinini sokunyakaza sihamba kancane sizothinta ukusebenza kahle kokugaya

Uma isivinini sokunyakaza siyi-fsat kakhulu, sizoholela ekulimaleni kwe-grindstone ngokushesha

Ukunyakaza okulungile:isivinini(mm/s)≈10/ububanzi bekhanda lensingo lamasaha(mm)

Isibonelo:305x96Tx3.2 isivinini sokunyakaza=10/3.2=3~3.5mm/s

I-impaci yesivinini sokunyakaza ngokushesha kakhulu:

1.I-Saws blade head paste.

2.Grindstone abrashe ngokushesha.

3.Yehlisa ukunemba kwamasaha.

4.Unsharp for amasaha blade

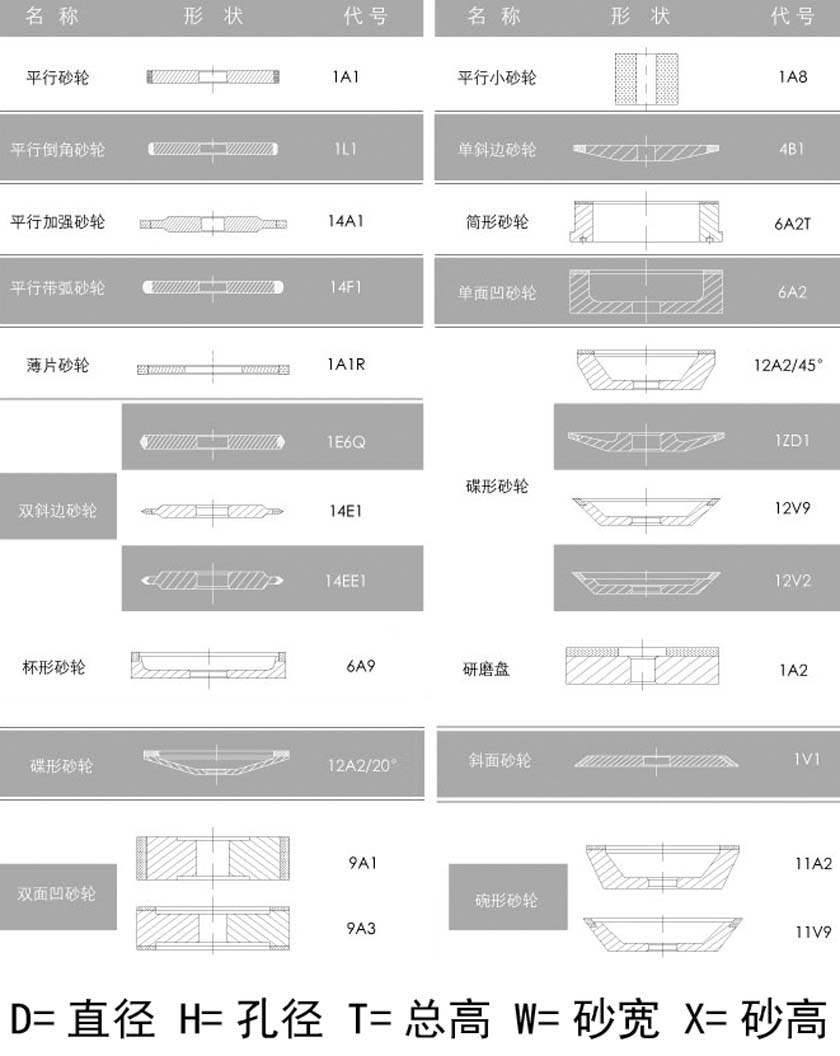

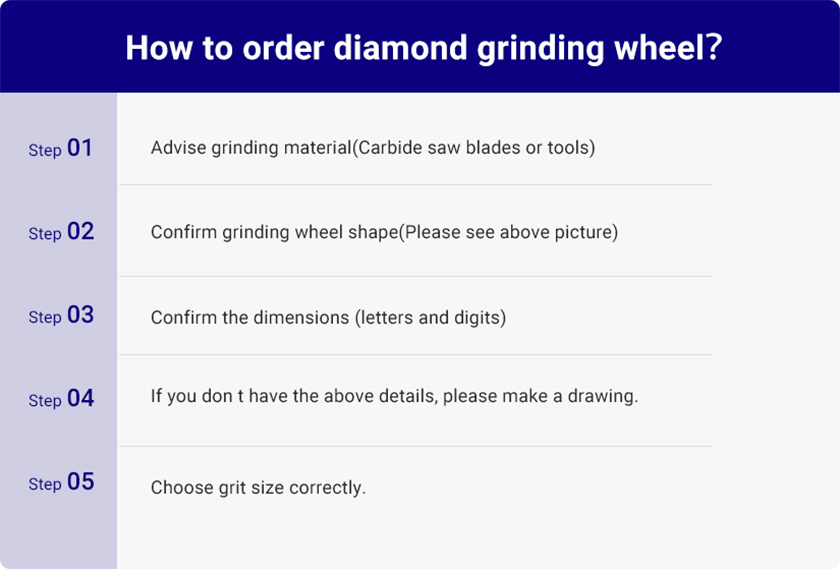

Amasondo edayimane anomumo ohlukahlukene ukuhlangabezana nezidingo zakho ezahlukene (1A1 1V1 14A1 14F1 11v9 12V9 6A9 6A2 12A2 4B1 .etc)

Ezinye zezithombe zivela ku-inthanethi.Uma kwenzeka kuphulwa umthetho, sicela usithinte nge-imeyili futhi ususe okunye